A well optimized manufacturing operation requires a keen understanding and application of maintenance. For most manufacturing operations, this often falls between two separate disciplines of maintenance: preventive or predictive maintenance. This post will provide a breakdown of each of these approaches in addition to detailing how they keep equipment in the best possible shape.

Preventive maintenance is the well-established standard within the manufacturing industry as a result of its simplicity. With this approach, maintenance is as simple as determining regularly scheduled intervals that match each equipment’s needs and performing maintenance accordingly. It’s important to note that older pieces of equipment may require more frequent checkups than newer equipment. The same can be said for equipment with varying run times, meaning equipment more frequently used will need additional tuning in comparison to equipment that is used sparingly.

As technology evolved, so too did the philosophy surrounding maintenance. With predictive maintenance, a more calculated approach can be taken. Through the use of integrated systems, optimal maintenance intervals can be derived from performance data of each machine. Certainly a more effective method to using an organization’s maintenance resources, but this method requires an expensive investment.

Despite the costs being so high, organizations that do invest into these systems now are contributing to the betterment of reliability of these systems. With more connections to the Internet of Things, the more the systems can understand. This leads to more advanced capturing, reporting and analysis as a result. With the most accurate data, improving efficiency and decreasing unexcepted downtime is much easier.

Unfortunately, for most businesses, these advantages aren’t able to outweigh the costs. With such high barriers to entry, businesses are left to preventive maintenance strategies. Rather than investing the initial capital for the systems and retraining of existing employees, businesses can reliably count on preventive maintenance. For businesses that can afford the investment, they must also be prepared for the challenges that come from this retraining.

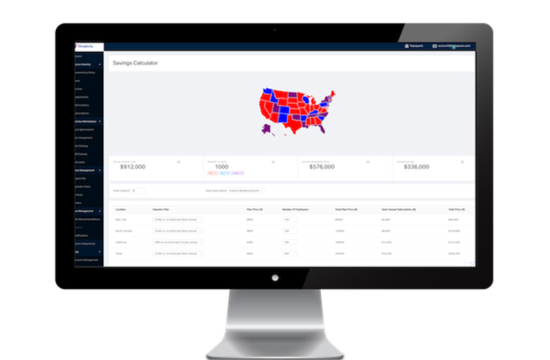

If you believe your organization is ready to take the next step in investing into these systems, it may be worth checking out the infographic coupled alongside this post. It includes more valuable information on how these systems can benefit your organization when correctly integrated. Continue reading for more of this information. Infographic courtesy of Industrial Service Solutions.