Ever since technology started integrating with various ways of doing things, manufacturing procedures have become far more efficient, sustainable, and smarter.

Now, these modern factories and industries around the globe are the new face of technologies with their smart way and technologically advanced infrastructures. This is Industry 4.0. It is a revolution of its own where companies are changing the way they do things to be smarter, more efficient, and more advanced.

In this article, we will focus on Industry 4.0 manufacturing and why it is such a significant factor. If you are ready, let us start right away.

Table of Contents

The Nine Pillars of Industry 4.0

Industry 4.0 is simply a concept that represents the 4th generation methods and ideas that are changing the manufacturing scene. This concept has nine main factors or ‘pillars’ supporting its advancements. Therefore, to understand the intricate details of Industry 4.0, you will need to understand these nine pillars. Let us take a look:

Data analytics

Recent operations have discovered the importance of data and what the right interpretation of big data can bring to a company. Industry 4.0 revolves around this factor, where studying and analyzing data can help you acquire useful insights, predict future events, and even be prepared for what’s to come.

IoT

Internet of Things or IoT is a concept where every actuator and sensor can operate separately while being connected in a controlled ecosystem. Industrial IoT is the same but a whole level better.

The Cloud

While we have already talked of the importance of data, storing and managing data, too, is just as important. Here is where the cloud comes in, with its storage space and great accessibility features that allow smooth communication and accessibility of data.

Autonomous Robots

Robots are no longer the future, and Industry 4.0 has seen to that. Autonomous robots are now a regular sight in the manufacturing industries, where they have helped to increase the productivity and efficiency of the environment with reduced risks and errors.

Simulation

Simulation is the process of using virtual reality to help create an environment based on real-time data. Such simulation has helped companies to test the productivity or effectiveness of new products, floor plans before any final changes are implemented.

Cyber Security

There are always two sides of the coin, and where there are so many advantages of digitalization, there is also the part that has initiated crimes related to it. This is precisely why cyber security is another strong pillar of Industry 4.0 that keeps raising its bars as technology keeps updating.

3D Printing

Various new techniques are being implied into manufacturing, one of which is 3d printing and additive manufacturing. It has truly helped the manufacturing industry to reach a new height of creations, with new opportunities and scopes appearing every day.

Augmented Reality

Another major supporter of Industry 4.0, augmented reality, has helped change the way of manufacturing by enhancing technician skills through it.

Integration (Vertical and Horizontal)

Vertical and horizontal integration refers to the connectivity of every device and system on their level to initiate better communication and flow of work without a missing piece.

Conclusion

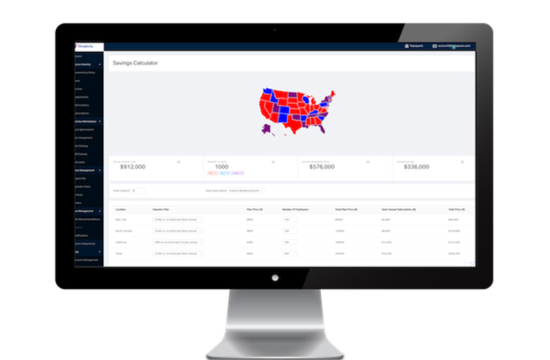

As a company, not updating yourself to the way of Industry 4.0 will not just make you fall behind but will slow you down and cost you money in the long run. Therefore, the best path is to have yourself updated with, for example, ANT Software for Industry 4.0 manufacturing to ensure that you do not miss out on the advantages that this revolution has to offer to you.